After posting I thought, why am I telling you this? Ha.

Cool. I just thought you were going more with “don’t take advice from a forum, go to a professional”. Outside forums are cool, but like I mentioned, the home improvement thread here is really good and someone would be better off going to the thread here than posting in some contractor forum where everyone will just tell you to hire a pro and/or you don’t know anyone and don’t know if they have generally been an idiot for the previous 10 years. YT is excellent and you can often find a video where you can see and hear exactly the same thing you are seeing and hearing irl.

Never hurts to change the spark plugs. Can make a huge difference.

I am attaching a cab fan to my compact tractor. I made a mount (U bolts attach plate to roll bar) and now need to do the wiring.

Two bare wires dangle from said fan. What is the preferred sort of connector to put on the ends? Something better than exposed wire nuts.

I presume the thing to do then is to run a cable as best I can to the fuse box.

Engineer for one of the Detroit Big 3 here. Despite working in this industry for nearly 20 years now, I’m not a traditional “car guy” like many of my co-workers. But I do know my shit, especially in my area of responsibility, which is diagnostic trouble codes. My actual job is to make sure the check engine light comes on when it should (when the car is not meeting emissions, or a critical component for detection goes out) and not a moment sooner. It’s actually a fun job because it crosses so many engineering disciplines. You have to know the ins and outs of how an engine works, the electronics and software that control it, and a bit of the chemistry that goes on. Prior to that I did wire harness designs for Fire Trucks, and before that it was acoustics testing for interiors. I may try to peruse this thread and offer advice where I can, although outside of products I have actually worked on, I’m probably not anymore helpful than the average mechanic.

Is it service vehicle soon, or service engine soon? Service engine soon is the OBD light, and should not be on without a trouble code that can be read with a standard code reader that can probably be had for like $20 (there’s also some smartphone apps and tools out there).

Other trouble codes that can set in other modules for non-OBD (emissions) reasons, often need specialized software that only dealers and authorized service techs have and can afford.

You’ll probably get to this, but it was “service engine soon” and I did buy a code reader and got a code for cylinder 5 misfire. The tool I borrowed must not have been working.

If you don’t mind me asking, which one? Domino’s, Little Caesar’s, or Hungry Howie’s?

Yep, see it now. Misfire is one of the most common trouble codes. Good luck. One common troubleshooting trick is to move the spark plug to another cylinder, and the coil to a different one. Then see if the misfire fault comes back on a different cylinder.

If it stays on cylinder 5, then it could be any number of things. Unfortunately all too often on older cars, it tends to be something pretty significant like a worn valve or piston ring. A leak down and compression test is usually the next step, and the tools for this can probably be rented from autozone (or even purchased) for a reasonable price. We have fishbone diagrams for diagnosing all the fault codes, and the misfire one is probably 10X bigger than for any other fault.

How you not gonna mention Little Caesars. The founder there owns like half of Detroit at this point.

Worth mentioning that service manuals for older cars can be found at good-sized city libraries in the reference section. You can’t check them out, but way better information than a Haynes or Chilton manual.

Brain fart at the time of typing. The joke was “the Big Three” were all pizza chains started in Michigan (also a statement about how manufacturing is dying in the midwest–it was a multi-layered jopke!) AFAIK, Pizza Hut wasn’t started in MI.

Edited to fix the joke, but it’s ruined now

I’d suggest butt connectors. Get them the right size for your wires. You’ll need a decent quality crimping tool. The cheap ones that are a combo wire cutter/stripper are crap. You can get this stuff reasonably at Harbor Freight if you have one nearby.

Ideally, I’d protect the wires with a plastic split wire loom tubing like this:

Routing it may be a pain. You can secure it with zip ties. You may need to get a little creative by gluing plastic mounts in strategic locations. Cheap at amazon.

Butt connectors work well. Don’t skip on the heat shrink either. Some have them built in. Preventing water intrusion is priority #1, 2, & 3 for electrical connections and components exposed to the elements.

Thank you.

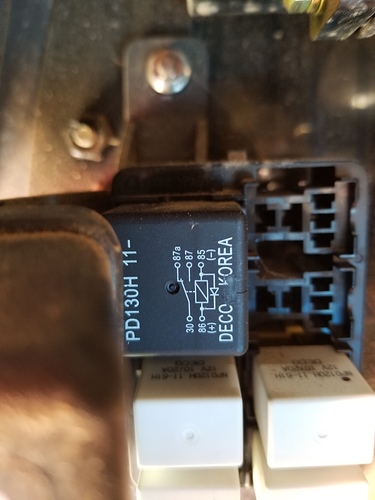

Next question is what to hook the fan to. Near the fuse boxes I found this prospective connection:

How do I determine what fuse these connection(s) are attached to?

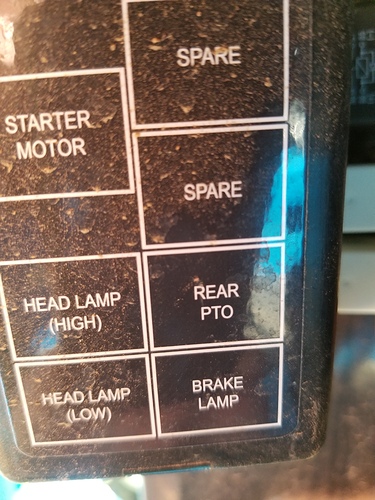

Here is one nearby fuse box:

Could life be so lovely as the dangling unused plug be associated with the spare fuse receptacles?

If so, what are this type of fuse called (associated with above schematic):

Those are relays (a type of electrical switch), not fuses. While you’re definitely up my alley when it comes to wiring systems, I have almost no clue what I’m looking at here. That loose dangling uncapped connector is giving me a panic attack just looking at it.

Generally when modifying a vehicles wiring system, you aren’t going to want to mess with the fuse box. They really aren’t meant to be tapped into. Presumably this simple fan just has a power and ground wire? What I would do is run a wire straight back to the battery, and put in an inline fuse at the battery. Then run that wire through a switch (I’m assuming you want this fan switched, yes?). Run the ground wire to just about anything metal, or back to the battery.

The connector could be for an accessory you don’t have, so might work out. The “spares” in this box are just spaces for unused relays (not fuses in this case), I think. So not connected to anything, no power there. A wiring diagram would be great if you had an accurate one for the tractor, but these aren’t necessarily easy to find.

The little black and white boxes are relays (electrically actuated switches), not fuses.

May be easier to start by figuring out what that connector isn’t, then eliminating that choice from what’s in the fuse box. A pic of the fuse box may help out here.

At the connector, you can use a multimeter or a test lamp to check for power. Use a bent paperclip and stick it in the holes to get access to the pins inside the connector. To see if power is available at a pin, you can use the voltmeter option of your meter or the test lamp. But it might be switched so not necessarily easy to tell.

Fuse box diagram:

There is also the below unattached wire going into the fuse box. I dismissed trying to use it because the wire is lower gauge than the fan’s, but would be happy to be wrong.

The tractor does not actually have a work lamp, despite what fuse box says. Fan users say they’ve used 15 amp fuses (also 10 and 20), so maybe that free wire is for a lamp and ready to use??

Contemplating your idea of going to the battery, the disadvantage being that this doubles the distance I have to run cable.

When you say a switch for the fan – you mean in addition to the one on the fan itself? Would that be necessary?

No, additional switch isn’t necessary if it has one on it and is in a location you can reach when you want to.